Hi all,

I've recently moved in to a new house! We moved in at the end of April. The house was built in 1912 and has 15 sash windows. The goal is to bring them back to their full glory.

They range from "pretty good, needs a repaint and draught proofing" through to "significant rot in the sill, bottom rail and stiles, why is there sheet metal instead of wood?!?".

I've given them all a quick assessment and have come up with the following:

I did reach out to Jim Sear (very nice chap) to see if he'd take up the task but unfortunately he's very much in demand and I'm too far away from him to be able to help. So i'm going to attempt to take them on myself, in no small part inspired by this post from Feltwell

My questions

I have a large garage that would work as a workshop and I'm happy to invest the money in getting the right tools for the job I have a lot of windows so it would still make sense if I can DIY to an acceptable standard. There are many other projects around the house i'll need to do such as building alcove cabinets and cupboards too.

Will appreciate any guidance

I've recently moved in to a new house! We moved in at the end of April. The house was built in 1912 and has 15 sash windows. The goal is to bring them back to their full glory.

They range from "pretty good, needs a repaint and draught proofing" through to "significant rot in the sill, bottom rail and stiles, why is there sheet metal instead of wood?!?".

I've given them all a quick assessment and have come up with the following:

- About half of them have rattling panes so I plan to remove and refit with new putty.

- All that I have checked so far open and close, sometimes stiffly. Nothing has been painted shut or had the top window nailed shut. No cords have failed.

- They have rather old plastic secondary glazing installed which I plan to remove once they are in better repair.

- All have flaking paint on frames and sills, I plan to strip and repaint.

- I plan to draught proof all of them – staff beads, parting beads, top and bottom rails.

- On at least one window, mentioned above, we have significant rot meaning i’ll need to replace some of the sash frame and sill.

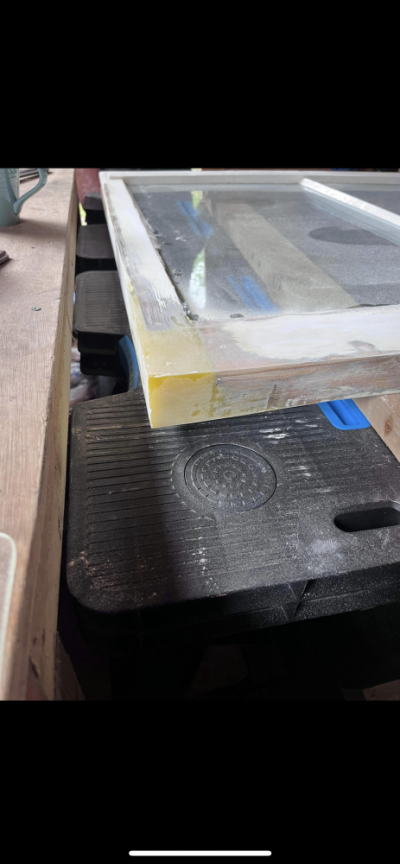

- The bottom rail has completely rotted and at some point has been repaired with sheet metal, quite a surprise!

- The bottom part of at least one of the stiles has also rotted significantly.

- There may be damage to the sash box and there has been water ingress through the sill, reaching the inside plaster below the window.

- The sill has rotted and appears to have been repaired at some point with concrete of some sort.

I did reach out to Jim Sear (very nice chap) to see if he'd take up the task but unfortunately he's very much in demand and I'm too far away from him to be able to help. So i'm going to attempt to take them on myself, in no small part inspired by this post from Feltwell

My questions

- Feltwell mentioned speaking to local joinery shops however I've failed to find any locally that would be able to cut me new rails, it seems to be mainly joiners who will build entire windows. Maybe I'm just not searching correctly. Any advice for North Hampshire/Surrey/Berkshire?

- For painting - Is linseed paint best or are there other options?

- I plan to draught proof all the sashes, purchasing staff and parting beads pre-installed with brushes/weatherstrips from Mighton or some of the other online suppliers.

- I’d also like to draught proof the top/bottom rails – I’ll need to get a router.

- Do you have any recommendations? Would a palm router be better or something larger?

- Assuming I can't find local joiners to cut me rails I'll be looking to go it alone - I'm up for the challenge!

- Where I need to replace any timber I think working with oak would be best for longevity – is this correct?

- For cutting/shaping rails/stiles and creating tenons I’ll need to get a table saw cant can cut oak and make deep enough cuts, are any other power tools other than table saw and router suggested?

- I would also need to rout the new rails meaning ovolo(?) router bit – would this be possible with palm router or should I get something a bit more robust?

- I have a very large collection of hand tools from previous projects.

I have a large garage that would work as a workshop and I'm happy to invest the money in getting the right tools for the job I have a lot of windows so it would still make sense if I can DIY to an acceptable standard. There are many other projects around the house i'll need to do such as building alcove cabinets and cupboards too.

Will appreciate any guidance