You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

DIY soda blasting?!

- Thread starter WetWales

- Start date

Flyfisher

Member

- Messages

- 10,285

- Location

- Norfolk, UK

Not me, but that's only because of the potential damage to the beams and the end result looking like driftwood. Personal choice I guess.

However, your 'close up' photo looks very much like my attic timbers that had been covered with a very soft paint - some form of distemper I believe - and I found it was fairly easily washed off with lots of water and a stiff brush. To minimise the potential mess, I bought a wet-n-dry vacuum cleaner (a 'George' as I recall, similar to a 'Henry') and a pump-up water sprayer. Using these and the 'stair brush' attachment on the vacuum, I could spray the beams to soften the distemper while immediately scrubbing with the brush with the vacuum sucking up all the water and dislodged distemper with hardly any mess at all.

Of course, that won't work if the beams are covered in a modern paint (as some of them seem to be in your photos) but it's quick and easy to test a small area with a stiff brush and a wet cloth. The attached photos show some before-and-after areas.

However, your 'close up' photo looks very much like my attic timbers that had been covered with a very soft paint - some form of distemper I believe - and I found it was fairly easily washed off with lots of water and a stiff brush. To minimise the potential mess, I bought a wet-n-dry vacuum cleaner (a 'George' as I recall, similar to a 'Henry') and a pump-up water sprayer. Using these and the 'stair brush' attachment on the vacuum, I could spray the beams to soften the distemper while immediately scrubbing with the brush with the vacuum sucking up all the water and dislodged distemper with hardly any mess at all.

Of course, that won't work if the beams are covered in a modern paint (as some of them seem to be in your photos) but it's quick and easy to test a small area with a stiff brush and a wet cloth. The attached photos show some before-and-after areas.

Oh yes ok I see what you mean, that old soft paint stuff I assumed was like an old whitewash , and some of it is slightly coloured blue which I’m told was done with the old sheep dye colouring!

But yes one room is like that old distemper stuff which does come off easily but the others are layers and layers of paint black and white,

I wouldn’t consider sandblasting but I thought soda blasting might be ok…

Thanks for your advice!

But yes one room is like that old distemper stuff which does come off easily but the others are layers and layers of paint black and white,

I wouldn’t consider sandblasting but I thought soda blasting might be ok…

Thanks for your advice!

Flyfisher

Member

- Messages

- 10,285

- Location

- Norfolk, UK

There have been various threads on here over the years discussing various forms of blasting, including dry ice, so might be worth some searching but the most important thing is to try a test area first to see what sort of end result you'll get because depending on your personal taste the end result might be worse than painted beams.

There are also chemical methods of removal and a forum favourite was 'Strippers of Sudbury' (just checked and they are now here: https://www.stripperspaintremovers.com/). I've never tried this method but search the forum for other members experiences. From what I've read, it works but can be a bit laborious, especially if the beams are a bit 'gnarly' and the paint has got into the cracks and grain of the wood.

There are also chemical methods of removal and a forum favourite was 'Strippers of Sudbury' (just checked and they are now here: https://www.stripperspaintremovers.com/). I've never tried this method but search the forum for other members experiences. From what I've read, it works but can be a bit laborious, especially if the beams are a bit 'gnarly' and the paint has got into the cracks and grain of the wood.

Do not underestimate just how much air is needed for blasting. Used to work for a fabrication shop that did a fair bit of blasting. Needed a diesel powered Hydrovane to supply enough air. I purchased a small spot blasting gun a couple of years back, swayed by the blurb on the side of the box that it only needed 5-6cfm. It needs a lot more to be effective.... Oh, and it eats blast media like there is no tomorrow.I’m wondering if anyone has attempted soda blasting their beams themselves?

I got a quote for our beams and it was over 9k

So even buying a compressor and the other stuff needed would be way cheaper!! Anyone done similar themselves ?!

Toby Newell

Member

- Messages

- 1,635

- Location

- Surrey

HiHi folks,

I’m wondering if anyone has attempted soda blasting their beams themselves?

I got a quote for our beams and it was over 9k

So even buying a compressor and the other stuff needed would be way cheaper!! Anyone done similar themselves ?!

Thanks for any insights or advice!

View attachment 12425

View attachment 12427

View attachment 12429

View attachment 12430

View attachment 12431

I have a good friend and colleague that has a virtually brand new professional soda blaster and compressor that is available to buy, the only caveat being it is in North London, so I don't know whether that makes sense seeing as it would be out of warranty and you would have transport costs. Feel free to DM me and I can pass on his details to you. I think it was probably quite a good one as he tends to buy the mid or top range tools, I do recall he bought a ton of soda at the same time but sadly that has deteriorated.

He bought it for cleaning brickwork but after only a few minutes use found it was too aggressive and so never used it since.

Toby Newell

Member

- Messages

- 1,635

- Location

- Surrey

I will probably pop up on many of those threads, the synopsis of which is actually very simple.

Blasting, of any sort, is very often the cheapest and quickest method of stripping old beams and architectural woodwork and there simply is no analogue. Another advantage is that they are very good at getting into interstices and so get timbers very clean, Also, although it is incredibly messy, at least the job is completed faster and so that mess is confined to a smaller time frame.

The first issue is micro damage, all blasting methods cause damage as does all stripping, but for sound timbers this damage is limited to a surface 'fuzz' which may or may not be acceptable but would need further processing (sanding) if you wanted to recoat it with a clear finish, this fact is often omitted from any marketing. The second issue is macro damage ie heavy pitting and breaking off of chunks of wood leaving a driftwood effect, this only happens with very old timbers that have a lot of worm damage and friable areas but it can really be quite disheartening to see.

I think it's important to realise, just like the damp industry, a lot of these restoration vendors over exaggerate their system as being overly 'gentle' no blasting is gentle (on wood) it has to fire media hard enough to remove the finish and always takes some wood with it (like sanding) ice blasting works on a different principle and is very good on metal, but be aware, it can be even more damaging on wood, always get a small test first.

Poultice stripping which is just NaOH or KOH in a thick paste, works well for very thick build ups but requires multiple applications over multiple days and then requires further washing, neutralising then sanding, also poking around to remove from in the grain with picks, scrapers and brushes, it's multiple times slower. Caustic strippers are pretty nasty and messy. DCM strippers are similar, they require more human input but work faster than the caustic poultice strippers.

I have never used blasting or poultice strippers only ever sanding, scraping and DCM but for large areas these methods aren't very practical or economical.

Soda blasting is one of the most gentle, there are others like TORC, these try and improve efficiency by combining water with the blast media and sometimes by introducing rotation into the stream, but they are all very similar.

Blasting, of any sort, is very often the cheapest and quickest method of stripping old beams and architectural woodwork and there simply is no analogue. Another advantage is that they are very good at getting into interstices and so get timbers very clean, Also, although it is incredibly messy, at least the job is completed faster and so that mess is confined to a smaller time frame.

The first issue is micro damage, all blasting methods cause damage as does all stripping, but for sound timbers this damage is limited to a surface 'fuzz' which may or may not be acceptable but would need further processing (sanding) if you wanted to recoat it with a clear finish, this fact is often omitted from any marketing. The second issue is macro damage ie heavy pitting and breaking off of chunks of wood leaving a driftwood effect, this only happens with very old timbers that have a lot of worm damage and friable areas but it can really be quite disheartening to see.

I think it's important to realise, just like the damp industry, a lot of these restoration vendors over exaggerate their system as being overly 'gentle' no blasting is gentle (on wood) it has to fire media hard enough to remove the finish and always takes some wood with it (like sanding) ice blasting works on a different principle and is very good on metal, but be aware, it can be even more damaging on wood, always get a small test first.

Poultice stripping which is just NaOH or KOH in a thick paste, works well for very thick build ups but requires multiple applications over multiple days and then requires further washing, neutralising then sanding, also poking around to remove from in the grain with picks, scrapers and brushes, it's multiple times slower. Caustic strippers are pretty nasty and messy. DCM strippers are similar, they require more human input but work faster than the caustic poultice strippers.

I have never used blasting or poultice strippers only ever sanding, scraping and DCM but for large areas these methods aren't very practical or economical.

Soda blasting is one of the most gentle, there are others like TORC, these try and improve efficiency by combining water with the blast media and sometimes by introducing rotation into the stream, but they are all very similar.

TudorCottage

Member

- Messages

- 115

- Location

- Bedfordshire

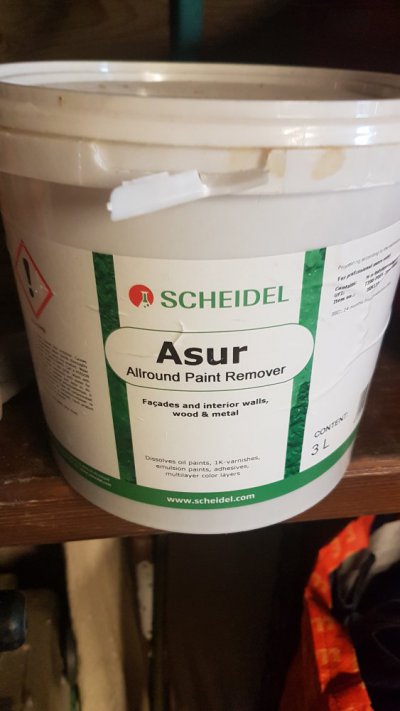

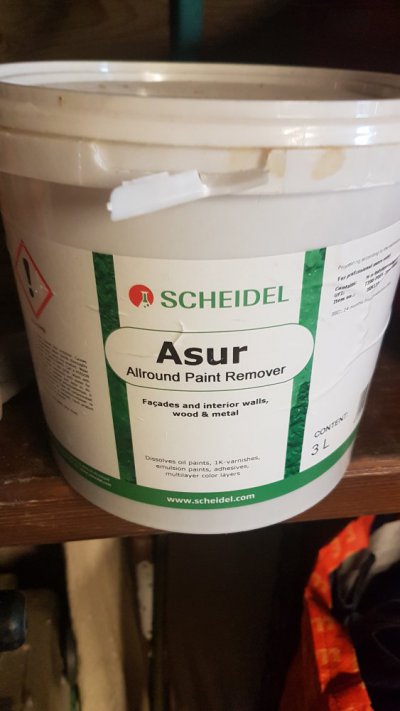

I used this stuff to strip the main beam in our living room. It has to be left on for a good few hours. I then agitated it with a stiff brush and hot soapy water. At first it looks like it hasn't done much but after a few days it drys out and removes most of the product that was on there. I didn't take any before pictures but it was like a dark brown mottled stain. Ignore the Christmas lights the grandchildren think it looks good to have them on in winter. They will be coming down in Spring.

Thanks for the replies everyone! Really appreciate it! I’ve read pretty much eveyrhing I can find on here and elsewhere about all the topics were covering on our house renovation! The beams continue to be the most… contentious…? If that’s the right word!

Maybe as I read on a thread soemhqere on here, it is down to personal preference as long as the beams aren’t too worm damaged which will obviously / could as you say Toby, strip big chunks off!

i might order some klingstrip and test that out see if it gets enough off that I can then try washing…. Orrrrr I haven’t actually tried yet but maybe scraping it WILL work as if they are all whitewashed first then that SHOULD come off easily and therefore paint will come off as it’s applied onto the whitewash!

Thanks for the insights!

I’m still interested in trying soda blasting (so Toby… i could be interested in your mates stuff!)

but I think I need to find out if / how bad the worm damage is but judging by the rest of the whole house I don’t see how the beams would have escaped them!

Much appreciated!

Maybe as I read on a thread soemhqere on here, it is down to personal preference as long as the beams aren’t too worm damaged which will obviously / could as you say Toby, strip big chunks off!

i might order some klingstrip and test that out see if it gets enough off that I can then try washing…. Orrrrr I haven’t actually tried yet but maybe scraping it WILL work as if they are all whitewashed first then that SHOULD come off easily and therefore paint will come off as it’s applied onto the whitewash!

Thanks for the insights!

I’m still interested in trying soda blasting (so Toby… i could be interested in your mates stuff!)

but I think I need to find out if / how bad the worm damage is but judging by the rest of the whole house I don’t see how the beams would have escaped them!

Much appreciated!

Toby Newell

Member

- Messages

- 1,635

- Location

- Surrey

As an antique restorer you are taught to always try the gentlest method first, then escalate as required. So that's washing first, then brushing, scraping etc.

Your beams don't look that friable from here but you just have to scrape some areas to see.

I have never used any blasting method to strip anything and never will, but I know in some instances it is the only economically viable solution, I guess my view might be a bit defeatist. I would prefer to leave something that is very hard to strip rather than blast. Sanding and scraping also damages the wood so it's an odd bias to have. There is never just one solution, you really just have to experiment.

Your beams don't look that friable from here but you just have to scrape some areas to see.

I have never used any blasting method to strip anything and never will, but I know in some instances it is the only economically viable solution, I guess my view might be a bit defeatist. I would prefer to leave something that is very hard to strip rather than blast. Sanding and scraping also damages the wood so it's an odd bias to have. There is never just one solution, you really just have to experiment.

Athers1971

Member

- Messages

- 94

Just jumping into this as we have some 'black' beams (all in one room) and some that are just 'dirty' from years of pipe smoke and 100's of years of grime. Will probably try klingstrip first.

What about oxalic acid crystals and water? Does that just remove grime or all it remove any paint?

And on the subject of badly worm damaged and friable sections of beams (talking roof purlins principally) what would you do to them? Should I try and remove the friable bits? Or leave well alone? I can attach some pics later.

What about oxalic acid crystals and water? Does that just remove grime or all it remove any paint?

And on the subject of badly worm damaged and friable sections of beams (talking roof purlins principally) what would you do to them? Should I try and remove the friable bits? Or leave well alone? I can attach some pics later.

Toby Newell

Member

- Messages

- 1,635

- Location

- Surrey

I have only ever used oxo as a mild bleach, it works especially well on iron stains, not sure it would do much as a stripper. It's best used boiling hot, so I guess being a boiling acid (about as powerful as citric or acetic acid) then it might have some oompf when washing off chalk paints and limewash. Again, being a boiling acid it might also remove some grime and grease but that's not it's primary use, which is a wood and metal bleach. ( kills algae and mould too and cleans patinated brass etc) Poutice strippers are designed for very thick films, you might find for thin layers of grease and dirt that a DCM solvent stripper works best. Friable areas are really a suck it and see affair. Structurally they aren't doing anything important, it's more aesthetics. You just try and be careful as you can, but if you fiddle around with them, some parts will crumble, that's just what happens.Just jumping into this as we have some 'black' beams (all in one room) and some that are just 'dirty' from years of pipe smoke and 100's of years of grime. Will probably try klingstrip first.

What about oxalic acid crystals and water? Does that just remove grime or all it remove any paint?

And on the subject of badly worm damaged and friable sections of beams (talking roof purlins principally) what would you do to them? Should I try and remove the friable bits? Or leave well alone? I can attach some pics later.

Assuming your quote was from someone accredited by either Stonehealth or Restorative Techniques, then you certainly couldn’t buy everything you need for way less. New kit will be £8-10k for the blasting unit alone (TORQ or VorTech), plus rental of a serious compressor and diesel to run it, £500/ton for the media aggregate. Although, you won’t know which media you need to remove just enough to minimise manage, without trialling media and pressure and distance to achieve the right effect with minimal dwell time.So even buying a compressor and the other stuff needed would be way cheaper!! Anyone done similar themselves ?

Then you’ll also need the sheeting and shielding for internal mess control, and there is immense mess! Internally you should also be wearing a full head covering mask respirator in a very enclosed space, so you’d be buying one of those too probably.

You would get your training form the supplier though at least, as operating them isn’t so straightforward.

There is no real secondhand market, for these brands, as they like to keep control of the kit being serviced correctly and operators being trained and accredited. So you’ll probably be stuck with the kit too.

That said, it isn’t rocket science, but it is a lot of trial and error and it is very very easy to do irreversible damage very quickly.

However, looking at your pics, if it we me I wouldn’t do it. The limewash residue can be brushed off or better still remove the loose and re apply to consolidate.. The beams that look more uniform and glossy, weren’t really meant to be seen and could be repainted.

If you’re seriously considering it, then I’d say dig a bit deeper in your research. I’ve gone through the process lately, came close to purchasing a TORQ system new, but only as I had an attractive buy back offer plus free media. I also can’t do all internal areas of my house in one go, so owning the kit and doing rooms as it suited was preferable to hiring people who’d rather hit the lot in one single job.

That said, I’m not currently doing the outside of our building myself, mostly as it was more cost effective to get a decent quote and not have to deal with all the on costs and clean up. Do not underestimate the obscene amount of mess and noise. The media gets everywhere!

However, for the inside, I might change my mind depending on our schedule… as I’d like to be in control of removal, much of which I’ll probably do by hand as by way of contrast, we have a lot of very nicely carved high quality beams inside from when the barn was converted to a dwelling in the 1600s which need more care.